There are 3 belts inside Niryo One (axis 1, 2, and 3).

A relaxed belt can be the cause of a failed calibration or movement command.

For each belt, we’ll show you how to detect if the belt is not tensed enough, and how to tense it more.

For tensing a belt, you’ll need a screwdriver or an allen key.

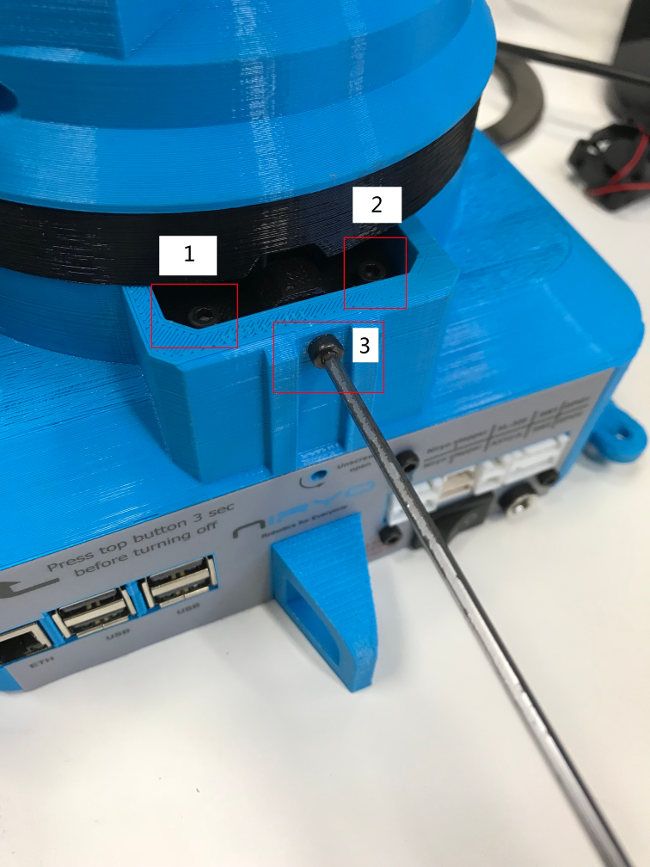

Axis 1 belt

You can check the belt tension when executing an auto calibration. If the belt is not tensed enough, the motor 1 will not stop when reaching the maximum position for the axis. You can hear a sound like “tac tac tac”. The calibration will fail because there is a 30 seconds timeout.

Loosen a little bit the screws 1 and 2, so the tension belt part can move. Then, tighten the screw 3 to tense the belt more. Finally, tighten the screws 1 and 2.

You can repeat this operation until you get a normal calibration. Note that you should not tense the belt to much either, this could also prevent the robot from moving normally.

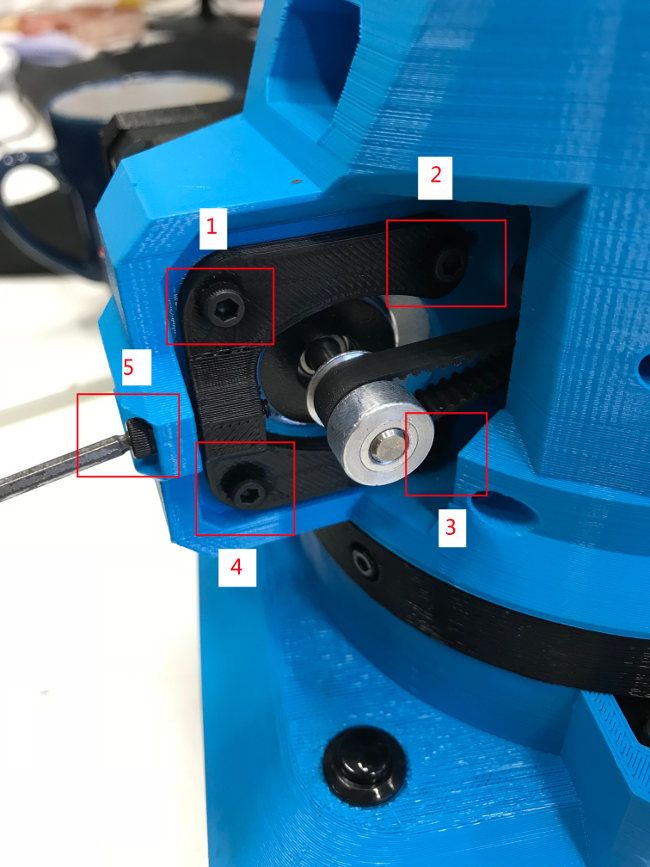

Axis 2 belt

If the belt of the axis 2 is not tensed enough, you’ll mostly have problems when executing move commands. The arm and forearm of the robot might fall down sometimes because the belt skids.

Loosen a little bit the screws 1, 2, 3, and 4. Then, tighten the screw 5 to tense the belt more. Don’t tense the belt too much or else the motor won’t be able to move the axis. You can then tighten back the screws 1, 2, 3, and 4.

Axis 3 belt

You can check the belt tension when executing an auto calibration. As for axis 1, if the belt is not tensed enough, the motor 3 will not stop when reaching the maximum position for the axis, and you’ll hear a “tac tac tac” sound.

Note that for the motor 3, hearing about 3-4 “tac” is ok. If you hear way more than 3-4 “tac”, or if the calibration just doesn’t succeed, then the belt is not tensed enough.

Also, when executing a move command using mainly the axis 3, for example to lift an object, if the belt seems to skid, you need to tense it more

Loosen a little bit the screws 1, 2, 3, and 4. Then, tighten the screw 5 to tense the belt more. Don’t tense the belt too much or else the motor won’t be able to move the axis. You can then tighten back the screws 1, 2, 3, and 4.

If you still have a calibration or move command problem

If all the belts are tensed enough, but one axis is still failing to auto calibrate, or execute a move command, then it might be :