The Industry Needs AI Connected to the Shop Floor

Labor shortages, cost pressure, and the demand for flexibility, European industry is undergoing a profound transformation. Automation is now a strategic lever to address these challenges, but it must deliver measurable value directly on the shop floor.

For manufacturers, the real question isn’t what robotics could become in ten years, but what can deliver value today: solutions that adapt, evolve, and generate measurable ROI.

That’s where Physical AI comes in: an approach that makes artificial intelligence truly operational in physical and industrial environments.

Physical AI: Intelligence That Perceives, Understands, and Acts

Physical AI refers to artificial intelligence embedded directly into physical systems (robots, machines, sensors), allowing them to perceive their environment, understand the situation, and act in real time.

The goal is to make the machine not just an executor, but a system capable of adjusting to environmental variations.

By combining AI algorithms, computer vision, sensory perception, and motion control, Physical AI enables autonomous, safe, and context-aware robotic behavior.

In practical terms, this means a robot can:

- recognize a new object or change in its environment,

- adjust its path or speed without reprogramming,

- learn new tasks from simple examples,

- and safely collaborate with a human operator without advanced expertise.

This real-world adaptability turns AI from an analytical tool into a driver of operational efficiency.

Making AI Truly Useful in Industry

AI is already used for predictive maintenance, quality control, or production data analysis. But too often, its potential remains confined to the cloud, far from the machines that create value.

Physical AI, on the other hand, brings intelligence directly to the machine level.

Its purpose: to simplify life for integrators and operators.

Where traditional systems require days or even weeks of setup, a Physical AI-based approach can significantly reduce integration.

Let’s take an example:

- An operator wants to add a new product reference on a production line.

- Instead of reprogramming the robot, they simply show the object or fine-tune the movement via an intuitive interface.

- In minutes, the robot learns, adapts, and performs the task precisely.

The result: less technical dependency, more agility, and immediate ROI.

That’s the promise of flexible automation that continuously adapts to production variations.

Reducing Hardware Complexity Through Intelligence

In robotics, hardware complexity often slows adoption. Each application requires specific configuration, integration expertise, and costly maintenance.

At Niryo, we believe the future of hardware lies in intelligence.

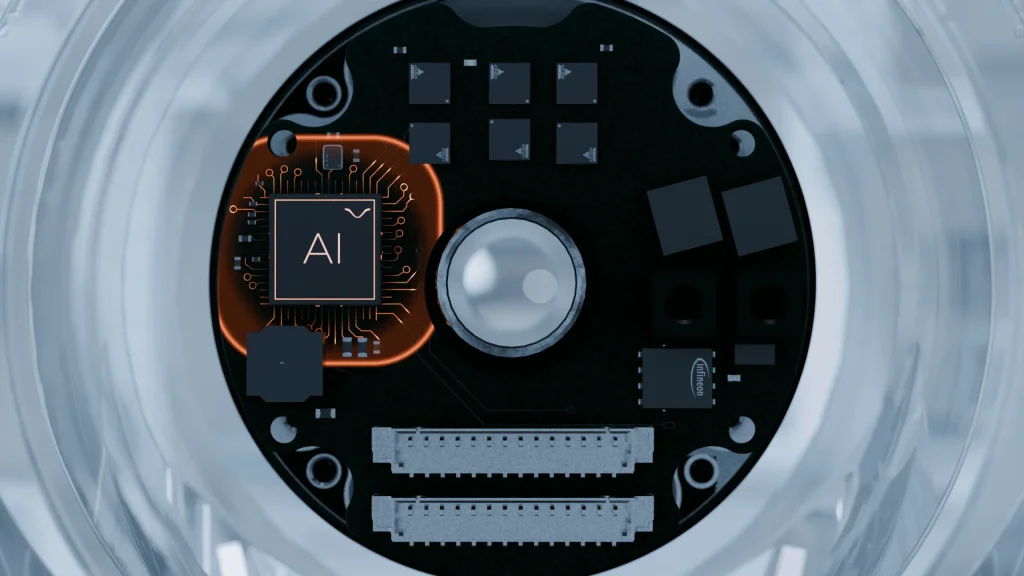

With our Nate robotic platform [Nate, the new robotic platform to elevate your factory], we use AI to make robots more autonomous across three key domains:

- Smart Vision and Environmental Adaptation:

Using a system of industrial cameras combined with machine learning models, the robot identifies objects in its environment and automatically adjusts its actions. In a smart pick use case, AI enables the robot to grasp the right object, refine its trajectory, and complete the task accurately, without manual reprogramming.

- Predictive Maintenance:

AI continuously analyzes sensor data to detect early signs of wear, anticipate failures, and optimize maintenance planning.

Result: fewer unplanned downtimes and greater machine availability.

- Programming Assistance:

We are also developing AI systems capable of translating natural language instructions into robotic commands.

The goal: to simplify programming and give operators more control in adapting robotic tasks even without specialized expertise.

This convergence of perception, understanding, and action makes robots more adaptive, easier to use, and more cost-effective to maintain.

This shift toward intelligent perception is already underway across the industrial ecosystem.

Companies like Inbolt (real-time 3D recognition for robotic guidance) and SensoPart (industrial vision sensors and embedded AI) are helping democratize advanced perception in production environments.

What Does It Change?

AI is no longer an add-on layer above the system, it becomes the engine of adaptability within the robot itself.

This approach enables simpler, more scalable industrial solutions, better suited to real-world, non-standardized environments where traditional automation reaches its limits.

Artificial Intelligence in Service of Industrial Performance

By embedding intelligence at the core of machines, Physical AI transforms industrial robotics.

It doesn’t replace operators, it empowers them.

It doesn’t promise a distant revolution, it delivers tangible evolution: greater simplicity, flexibility, and performance, here and now.

In a world where every manufacturer strives to do more with less, Physical AI embodies the spirit of Industry 5.0, bringing together artificial intelligence, industrial performance, and human expertise.

This vision “making AI truly useful to industry” drives every development at Niryo.