Global Industrie 2026 – Niryo introduces Nate, its new industrial product line

0

Global Industrie 2026

Niryo introduces Nate, its new industrial product line

Global Industrie 2026 – Niryo introduces Nate, its new industrial product line

Global Industrie 2026

Niryo introduces Nate, its new industrial product line

Simulate a robotic palletizing

Share

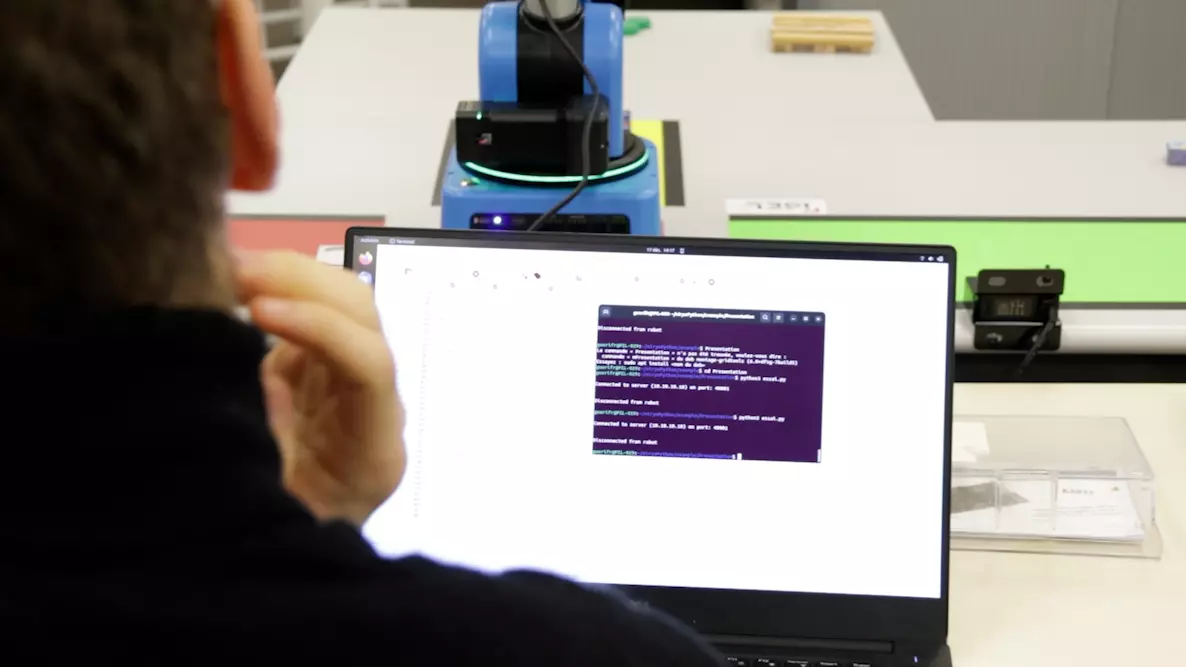

The automation of palletizing processes is becoming increasingly widespread, and ISEL Le Havre is well aware of this due to its industrial location. That’s why they decided to equip themselves with Ned2 6-axis robot arms to quickly and efficiently replicate palletizing using industrial robots.

The aim is to familiarize students with this world, which will play an important role in tomorrow’s businesses. Through projects, students can begin to get the grips with robotics, and program real-life situations to project themselves into the professional world!

During our visit, we had the opportunity to chat with Francois Guerin, a teacher and researcher in automatic electronics and robotics.

He gave us a detailed explanation of how Niryo’s robotic arms are used:

“As part of the course on the automation of logistics processes (2nd year), the students have a project to carry out on a robotized palletizing operation. Ordered goods are conveyed by two conveyors and placed on a pallet by the Ned2 robotic arm. The aim is to discover the benefits of robotic handling to help operators carry out repetitive and difficult tasks.”

“More generally, we use Ned2 robotic arms to be able to reproduce a logistics use case on a reduced scale. But also to discover handling robotics, the application of computer science (Python, networks, …) and electronics (sensors, IoT, …) courses.

For ISEL Normandie Le Havre University, the Ned2 robotic arm is a good teaching tool, as Mr Guerin points out. It’s an open tool, open to programming with conventional tools.

The students who use the robot do so with Python, which means they can really get hands-on experience of the world of logistics.

“The only limit is our imagination. As long as it’s open source, it’s easy to design and develop.” sums up Mr Guerin.