In an era of rapid technological advancement, a crucial question arises: how can education bridge the gap between theoretical knowledge and the practical skills required in industries? Current education often struggles to fully prepare students for the specific challenges of automation and technology.

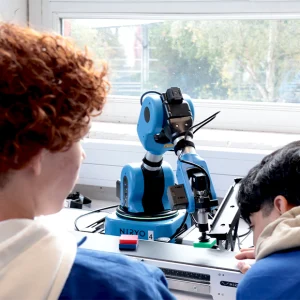

How can robotics education be redesigned to create a direct and effective link with the requirements and opportunities of the industrial and service sectors? It is imperative that we adapt our educational approach to equip young people with the necessary skills, particularly in programming and artificial intelligence. Robotics training in education and industry must focus on practical activities and hands-on workshops, using kits and digital tools, so that learners can learn to program and solve complex problems. School and university programs based on real-life industry cases can prepare students for working with robots in their future professional career.

The reality: a gap between theory and professional practice

Current robotics education is paradoxical. On the one hand, it provides students with a solid theoretical foundation and valuable familiarity with fundamental robotics concepts. On the other hand, there are still significant gaps: a lack of hands-on practice, sometimes using outdated tools and technology, and insufficient exposure to real industry challenges, especially when it comes to automating complex processes.

Current robotics education

It excels at imparting fundamental knowledge and preparing learners to understand how programmable robots work and how to program them. However, the training struggles to integrate the operational dimension. A lack of practical activities and programming on modern equipment hinders the development of essential skills.

Companies’ needs

Businesses are looking for versatile and operational profiles, equipped with critical thinking skills who can solve complex problems. They value mastery of specific software (API, ROS, industrial PLCs), as well as teamwork, and project management. Automation and artificial intelligence are transforming the industry and require a workforce that can integrate innovative robotic solutions.

This gap between educational preparation and professional expectations poses challenges for young graduates entering the job market and creates a talent shortage for companies, hindering innovation in the world of robotics.

Building bridges: strategies for connected teaching

For educational robotics to be truly effective, it is essential to revamp school and university curricula. This involves integrating practical modules, such as workshops on designing, manufacturing, and programming of industrial or service robots. Additionally, teaching must cover emerging technologies, such as embedded AI, collaborative robotics, computer vision, and IoT for robotics, with regular content updates. These updates are necessary in order to keep pace with technological advances and market needs.

Develop concrete, interdisciplinary projects

In-depth learning requires concrete projects. Students should carry out final projects or practical work based on real-life cases provided by companies. Robotics competitions, such as RoboCup or Eurobot, are excellent activities for fostering teamwork, creativity, and project management under pressure. Access to laboratories equipped with professional robotics equipment (robotic arms, AGVs, vision systems, etc.) is also fundamental to acquiring practical skills.

Promote collaboration with the business world

Collaborating with businesses is essential to ensuring comprehensive training in educational and industrial robotics. Integrate mandatory internships and work-study programs that allow students to experience extended workplace immersion. Invite professionals, such as engineers, technicians, and robotics company executives, to share their experiences and expectations. Establish research and development partnerships with them on innovative projects. Creating industrial chairs dedicated to robotics can also strengthen these connections and ensure relevant education and the continuous development of automation skills.

The benefits of a robust bridge

Teaching robotics in a way that connects it to the reality of industry offers considerable advantages for everyone involved.

For high school and college students

Young learners who engage in this type of training acquire technical and cross-disciplinary skills that are directly applicable, thereby enhancing their employability and facilitating their entry into the workforce. They develop a better understanding of the sector’s challenges and opportunities, which sparks their curiosity and passion for robotics. This educational approach enables students to learn how to program robots for learning, understand artificial intelligence, and become familiar with digital technologies, which are essential tools in today’s workplace.

For teachers and educational institutions

For teachers and schools, this connection enhances the value and appeal of the training to future students. It promotes the updating of knowledge and teaching practices, thanks to relevant resources and constantly updated content. Integrating STEM (science, technology, engineering, and mathematics) approaches into learning pathways also optimizes teaching effectiveness in educational and industrial robotics. Strengthening ties with the local and national economic fabric contributes to innovation and applied research, placing institutions at the heart of robotics development.

For businesses and the economy

Businesses benefit from access to a skilled and immediately operational workforce trained in the latest automation technologies. This increases their competitiveness and capacity for innovation, while reducing internal training costs. Creating an ecosystem that fosters the development of robotics benefits the entire economy by strengthening the industry’s position in the global technological landscape. This synergy between education and industry is the key to a promising future for robotics.