0

Discover Industry 4.0

Share

Niryo has developed its own conveyor with infrared sensor and storage ramp, capable of being piloted by the robot but also autonomously with its control box. Use Blockly or Python to control the conveyor’s speed and direction. Integrate your vision program with the supplied tags and design a truly intelligent, automated industry 4.0.

Niryo makes many gripping possibilities with a variety of electric, pneumatic and magnetic grippers. But it doesn’t stop there ! Thanks to the 3D models of our grippers available for free on our website, and the accessible panel control, you can develop your own gripper jaws and benefit of various applications with grippers adapted to your factory.

Niryo provides a suite of tools and kits such as a vision Set Kit, a Conveyor Belt Kit, and an assortment of versatile grippers.

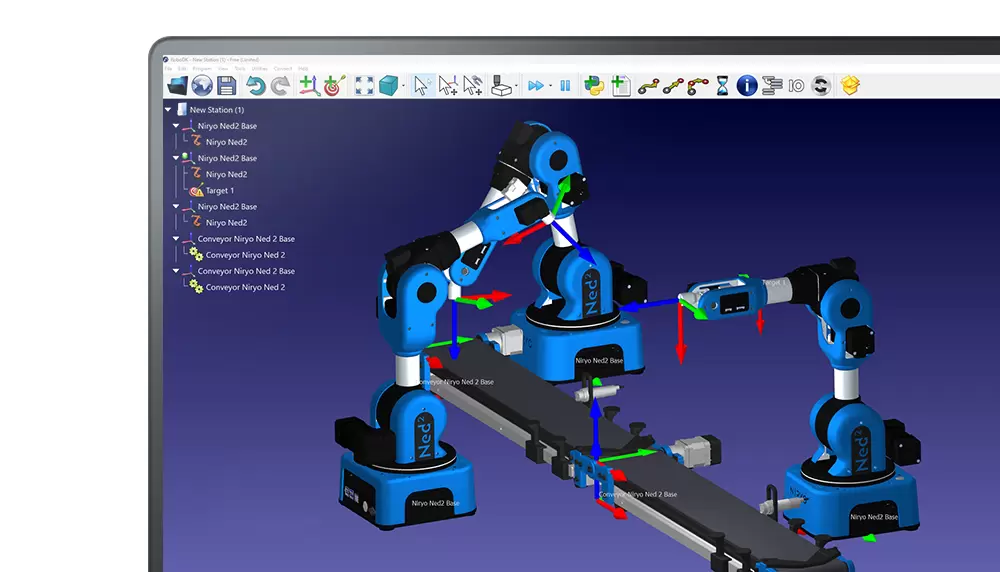

Thanks to our digital twins, simulate your production line and the interaction between robots easily with Matlab and RoboDK. Create a controllable HMI with Node Red. Make our robots interact with mobile robots and design a real robotics learning space based on industry 4.0