Last months, we wrote about packing and one of its feature, mixing, so it was all natural to write an article about another important logistical task: unpacking.

What is unpacking?

In the industrial field, unpacking corresponds to any task consisting in removing a product from its packaging. This manipulation allows the supply of a production line.

In context

A fragrance factory calls on a glass bottle supplier. These empty bottles are unpacked at the beginning of the production line in order to be, later on, filled with perfume, packed and shipped.

But unpacking can also happen at the beginning of a logistical line, for co-packing. In that case, an added-value task is made on the products. Among them, we can mention:

- the implementation of bipack;

- kitting;

- the implementation of boxes / cases.

In context

A logistical center creates Christmas sets with a perfume and a cosmetic sample in it. The samples and the perfumes are unpacked, by an operator, at the beginning of the line, and assembled in each set by another operator.

The variations of unpacking

Nevertheless, the products can be packed in various forms. Indeed, they can be packed in RSC (regular slotted container), shrink wrapped packaging, on a pallet or bulk goods.

Some packaging needs a more important human action than others, producing more waste. Nowadays, there are no ideal solution in the industry.

Robotizing unpacking tasks

Unpacking tasks need, most of the time, to manipulate medium-heavy loads repeatedly, which can cause operators multiple musculoskeletal problems.

In addition, these tasks have a small added-value, which means that they don’t need any particular expertise, but a great dexterity.

These arguments lead industrials towards the automation or robotization of these workstations.

Once this task is automated, the operator can perform another task needing his expertise.

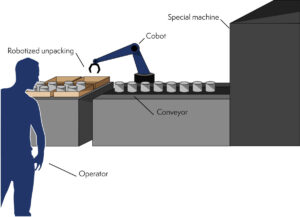

An exemple of implementation

The keys to a successful automation

The robotization of unpacking can seem easy, nevertheless, some parameters need to be taken into account.

- The supplying of the products: the robot is autonomous as long as there are products in the picking zone. If the zone is empty, the action of an operator is necessary. This change creates a “blank” in the production that must be quantified in the study phase of the project.

- The gripping: if the robot has to grab multiple products, depending on the manufacturing orders, then multiple grippers will have to be included in the study.

- The drop: the drop of the products can be either static or dynamic. During a static drop, the drop zone is steady, which makes the robot’s trajectory easier. However, if the dropping is made on a moving zone (on a conveyor belt for instance), the robot must adapt its trajectory to the speed of the conveyor. This feature is called tracking.