Day after day, the world is becoming increasingly automated. Terms like “robots”, “Tech”, “artificial intelligence” and “smart industries” are often used interchangeably and are playing an important role in our daily lives.

Yet, here you are, wondering whether you need to shift to a smart industry, or not. To buy that robot, or not. To invest in automation… Or not…

Whether you’re a startup or a big industry,

A local or an international company,

Whether you’re in manufacturing, healthcare, agriculture or transportation,

This article is for you.

We know that it can get complicated to make the right decision with so many different types of robots available. In this article, we will explore 5 key factors that you need to consider when selecting a robot. Whether you are looking to automate your business operations, improve your personal productivity, or simply satisfy your curiosity, this guide will help you make an informed decision and choose the right robot for your unique requirements.

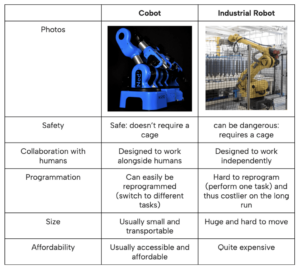

Before we dive into the criteria, you should be able to differentiate between a cobot and an industrial robot.

Please note that not all cobots have those advantages, it all depends on the manufacturers.Now that you have a clearer idea about the difference between the two, let’s take a look at the points you need to focus on when choosing the right robot for your industry:

1- Automation objectives:

What is your number one objective? Is it to improve throughput? To shorten the production cycle? To minimize waste? To free workers from tedious tasks and to improve their safety in the field? Or to maximize production quality?

Once you answer this question, you’re one step closer to your decision. In fact, collaborative robots can improve the experience of your workers while delivering better performance and quality. While industrial robots are aimed exclusively at increasing your production speed and quantity. So your final decision will depend on what you really want to improve on your production line.

2- Production line:

Once you’ve set your priorities and objectives, you should include the following factors into your decision:

Performance and production cycle: Here we should note that industrial robots offer superior technical features to collaborative robots. They are often faster, more precise, more powerful and go further. This means they improve your cycle times and your rate of return. However, cobots can also have a big impact on your performance. and that leads us to the second point.

Quality and volume of production: As we mentioned, industrial robots are designed to operate in high-volume manufacturing processes with small variations. Therefore, they are not easily reprogrammed and redeployed to new cell parameters and part configurations.

Cobots, on the other hand, can flexibly adapt to part variations. You can define different programs according to your needs and easily switch between them. This makes cobots ideally suited for short-run manufacturing processes.

Parts size and weight: Industrial robots are designed to execute tiresome tasks, like lifting and handling large, heavy parts that can be difficult to reach. This capability is particularly useful for aerospace components manufacturers, given the size of parts and the complexity of the manufacturing process overall.

Meanwhile, collaborative robots excel with small and medium-sized parts and rely on their respective reach capabilities. Hence, in the electronics industry, the collaborative robots’ abilities to handle delicate parts with precision and adapt quickly to changes make them a valuable asset.

3- Physical environment:

Industrial robots require fences for safety reasons, that’s why they can take up a lot of space. Most of the time, they require a full remodeling of the working space.

On the other hand, collaborative robots work safely alongside your employees, their compact size saves you a lot of space and makes it easier for your workers to move around.

Buy your cobot, teach your cobot, and you’ll be ready to go!

4- Collaborators:

Employees and regulations play a very important role in your decision process. If you’re surrounded with expert automation engineers, then implementing industrial robots is feasible.

Cobots don’t require specific skills to code them, since you can teach tasks with a simple motion, and they will repeat it easily.

5- Budget:

Traditional robots tend to be more expensive than cobots. Besides your budget for the automation process, don’t forget to consider the long-term costs of both options, including maintenance, downtime, and the costs associated with integrating the robot into your workflow.

Now that you have all the information, it’s time to decide! So what’s it going to be?