When it comes to educating the next generation of engineers and scientists, robots play a critical role in introducing students to automation and advanced manufacturing.

However, the struggle consists in choosing the right type of robot for classrooms, whether we’re talking about technical high schools or higher education such as engineering schools and universities. Three types of robots that are particularly well-suited for educational purposes are SCARA, Delta, and 6-axis robots.

In this article, we will be comparing and contrasting these three types of robots for educational use so we can help you choose the best according to your needs.

Before we start, let us define the aforementioned three types of robots:

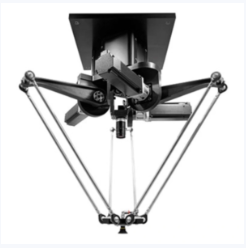

Delta robots

Delta robots are parallel robots that consist of three arms connected to universal joints at the upper base. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector.

SCARA robots

The SCARA is a type of industrial robot that stands for “Selective Compliance Assembly Robot Arm” or “Selective Compliance Articulated Robot Arm”. Both can be found.

It’s commonly known for its high speed and accuracy.

6-axis collaborative robots

6-axis cobots such as Ned2 are a form of articulated robots that are known for their ability to perform an extensive range of applications, thanks to their flexibility, reach, and strength.

Now, let’s compare the three in terms of price, axis, speed, diversity of applications and open-sourceness.

Price: robots aren’t born nor priced equally

The cost of cobots can vary depending on various factors such as size, features, and complexity.

Delta Robots tend to be the most expensive of the three types. Small Delta cobots suitable for education purposes usually range from $10,000 to $50,000 depending on the specific features and capabilities.

Scara robots are generally less expensive than Delta cobots, with prices ranging from $5,000 to $25,000 for small robots designed for education purposes.

6-axis cobots are often the most affordable of the three types, with small cobots for education purposes ranging from $3,000 to $20,000.

It is worth noting that these price ranges are approximate, and the actual cost of each cobot can vary depending on the manufacturer, supplier, and other factors such as customization options and add-ons. In general, 6-axis cobots tend to be the most affordable, while Delta cobots are typically the most expensive. Scara robots fall somewhere in between.

Ultimately, the cost of the cobot will depend on the specific needs and budget of the education program.

Axis and flexibility

The number of axis a robot has affects its range of motion and precision. Scara robots typically have three or four axis, which means they can move in three dimensions, but cannot rotate like a human wrist.

Delta robots have three axis and can move in all three dimensions, but have limited rotation. 6-axis cobots have axis that can move in all six degrees of freedom, allowing for greater precision and flexibility.

Speed

Speed is an important factor to consider when choosing a robot. It affects the robot’s performance in different applications, and it can also affect how much time it takes to program the robot for a specific task. Unless the robot will be used for educational purposes, then speed won’t be a crucial consideration. Adequate motors play an essentiel role here too.

The speed of each type of robot is measured by its cycle time (the amount of time between two consecutive movements) and acceleration/deceleration rate (how quickly or slowly it moves).

The speed of a robot is an important factor in its performance. Scara robots are the fastest of the three. The higher speed of Scara robots makes them ideal for tasks that require quick movements, such as pick-and-place operations.

The precision of 6-axis cobots makes them equally suited for tasks that require accuracy, such as welding or assembly, and that’s what’s make them also suitable for research and learning.

https://www.youtube.com/watch?v=I2Qokl7YHxU

Diversity of Applications

Each type of robot has a range of applications for which it is best suited.

Scara robots are ideal for fast pick-and-place operations, assembly, and packaging, while Delta robots are well suited for tasks that require a large working envelope, such as sorting and inspection.

6-axis cobots are highly versatile and can be used in a wide range of applications, including welding, pick-and-place, and assembly.

Size and practicality

The size of a robot is important because it affects how versatile and compatible it is with different workspaces.

Delta robots are typically the largest of the three and require a relatively large workspace. However, there are also smaller versions of Delta cobots available. However, its architecture with the base being fixed to a ceiling makes it difficult to test a variety of applications and projects.

On the other hand, Scara robots are typically smaller than Delta robots and have a more compact design.

6-axis cobots are available in a variety of sizes, but there are also small options available that are suitable for education purposes. An example of a small 6-axis cobot is Ned2, It has a footprint of 320 mm x 220 mm and a height of 500 mm, which makes it a good option for small classrooms or labs with limited space.

Ned2 is designed to be affordable and easy to use, making it a great choice for educators who are looking to introduce robotics to their students.

https://www.youtube.com/watch?v=qgAkwL_1AK0

What about open sourceness?

Open source compatibility is an important consideration for educators who want to customize their robots or integrate them with other technologies. Scara robots are the least compatible with open source software, while Delta robots offer some degree of open source compatibility. 6-axis cobots are typically the most open source compatible, with a range of software and programming options available.

For instance, Ned2 employs Raspberry Pi as its hardware and utilizes Python and C++ as its programming languages, in addition to ROS as its software. Moreover, our Niryo Studio application provides students with the opportunity to program the robot via Blockly, a visual programming language that can help them explore various aspects of robotics.

To conclude…

Each type of robot offers unique advantages and disadvantages, making them suited for different applications. Scara robots are the most affordable and fastest, making them ideal for pick-and-place operations and packaging. Delta robots have a large working envelope and are well suited for tasks that require a high level of precision. 6 axis robots are highly versatile and can be used in a wide range of applications.

For educators, the best choice will depend on the specific needs of their program, but 6-axis robots are likely the most versatile and adaptable option due to their open source compatibility and flexibility.