Are you familiar with collaborative robots, also known as cobots? In the recent years, the rise of cobots has revolutionized the field of industrial automation and advanced technical education. As we look ahead, it becomes increasingly evident that the future of cobotic technology lies in emphasizing flexibility over productivity.

These intelligent machines have transformed the way we work by seamlessly integrating with human operators to perform tasks that require precision, agility, and flexibility. While productivity will always be important, the ability of cobots to adapt to changing needs and work alongside humans harmoniously will be the key to unlocking their true potential.

The evolution of cobotic technology

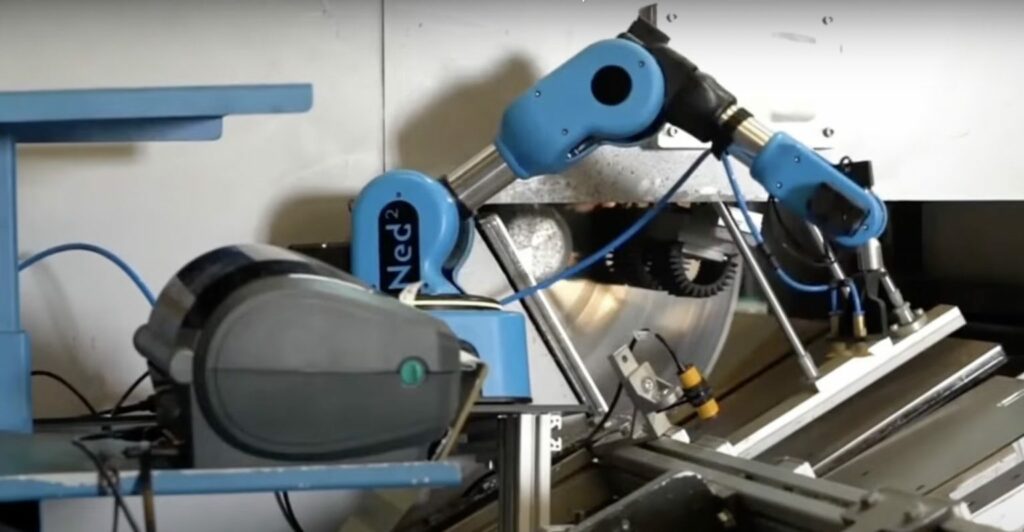

Cobots have come a long way since their inception. Initially designed to work in isolation within restricted workspaces, modern cobots have evolved to be more flexible and capable of collaborating with human workers.

Traditional industrial robots were designed to perform repetitive, high-throughput tasks, but cobots can handle a wider range of operations and are easily trainable, making them suitable for smaller batch production and highly dynamic environments.

Flexibility means collaboration

One of the most significant advantages of cobots is their ability to adapt and work closely with human counterparts.

Unlike their larger and more traditional robotic counterparts, cobots are built to be inherently safe, featuring advanced sensors and intuitive programming interfaces that enable them to detect and respond to human presence. This allows for direct interaction and collaboration, resulting in more efficient workflows and improved productivity.

By prioritizing flexibility, cobots can seamlessly switch between different tasks and adapt to changing production demands. This characteristic is particularly valuable in industries that experience frequent product variations or require customized manufacturing processes.

Cobots can generally be easily reprogrammed or taught new tasks, reducing the need for complex and time-consuming reconfiguration.

This flexibility empowers human workers to focus on higher-value activities while cobots handle repetitive or physically demanding tasks.

Beyond collaboration: empowering Human-Cobot Synergy

Another crucial aspect of the future of cobotic technology is the notion of human-cobot synergy.

Rather than replacing human workers, cobots are designed to collaborate with them, creating a symbiotic relationship that enhances overall efficiency and job satisfaction.

By taking over monotonous, physically taxing, or hazardous tasks, cobots free up human workers to engage in more intellectually stimulating activities, such as problem-solving, decision-making, and creative thinking.

Cobots can also contribute to upskilling and reskilling the workforce. With their intuitive interfaces and user-friendly programming, cobots allow workers to learn and interact with robotic systems more easily. This helps bridge the skills gap, enabling employees to acquire new competencies and take on more challenging roles within the organization.

Addressing Workplace Dynamics and Adaptability

The future of cobotic technology lies in its ability to seamlessly integrate into diverse work environments.

Cobots should be designed to navigate complex and changing surroundings, allowing them to work effectively in industries that require continuous process optimization. For instance, cobots in logistics and warehousing can effortlessly collaborate with human workers in dynamic environments, adapting to changes in inventory and operational needs.

Furthermore, cobots should be highly customizable to suit specific applications and industries.

This adaptability will allow organizations to deploy cobots across a wide range of tasks and sectors, from manufacturing and healthcare to agriculture and hospitality. By prioritizing flexibility, cobotic technology can evolve to meet the unique demands and challenges of various industries, unlocking untapped potential and driving innovation.

As cobotic technology continues to evolve, its true potential lies in prioritizing flexibility. By enhancing collaboration, empowering human-cobot synergy, and addressing workplace dynamics, cobots can revolutionize the way we work, creating a harmonious balance between humans and machines.

The future of cobotic technology offers exciting opportunities to improve efficiency, job satisfaction, and adaptability across various industries.

Remember, the future is Industry 5.0, which is all about collaboration, so that humans can get back their places in the production process.