Choosing different parts of a robot might get a little complicated especially with the various options available on the market.

When it comes to motors, the decision never gets easier. In fact, robots rely on high-performance motors to drive their movements and perform their tasks with precision and speed.

There are many different factors to consider. In this article, we will discuss some of the key criteria to consider when choosing a motor for a collaborative robot dedicated to research and education.

1. Power and Torque

The power and torque requirements of an educational robotic arm are typically lower than that of industrial arm robots, but still depend on the intended use of the robot. If the robot is designed for heavy lifting or precise movements, it will require a motor with higher power and torque. In general, a motoreducer with a power output of around 50-100 watts and a torque of 0.2-0.5 Nm is sufficient for most cobots made for education.

More info on this video showcasing precise data about Ned2 and its capacities:

2. Maximum Acceleration

The higher the reducer’s gear ratio is, the higher the maximum acceleration of the motor will be.

The maximum acceleration of the motor is also an important consideration when selecting a motor for an educational arm robot. The motor should be able to accelerate and decelerate quickly, to ensure that the robot can perform fast and efficient movements.

3. Affordability

Usually, universities and schools look for affordable materials for their classrooms, especially because they tend to purchase important quantities to ensure a fair educational experience for each student.

Cost is often a limiting factor in educational settings. While it’s important to select a motor that meets the requirements of the robot, it’s also important to balance cost with performance. In general, a motoreducer with a price range of $50-$200 is suitable for most educational arm robots.

4. Power Density

Power density refers to the amount of power that can be generated by the motor in relation to its size and weight. In general, a motor with a higher power density is preferred for educational arm robots, as it allows for a more compact and lightweight design. A motoreducer with a power density of around 1-2 kW/kg is suitable for most cases.

5. High Speed Capability

While industrial robotic arms often require high speed capabilities, those designed for education typically have lower speed requirements. However, a motor with high speed capability can still be beneficial in certain applications, such as when the robot needs to perform fast movements or when a higher operating frequency is required according to the robotic use cases.

The speed of an educational arm robot depends on its intended use, but generally, a motoreducer with a speed range of 10-100 RPM is sufficient for most applications. The motor should also be capable of maintaining consistent speed throughout its range of motion, to ensure accurate and precise movements.

6. Reliability

Reliability is a crucial factor when selecting a motor for an educational robotic arm, as these robots are often used for teaching and learning purposes. The motor should be designed to operate consistently and reliably, with minimal maintenance required. It’s also important to select a motor from a reputable manufacturer with a good track record for quality and reliability.

What’s next?

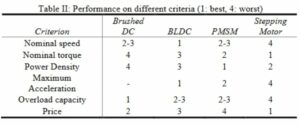

Once you’ve matched your needs with those criteria, you’ll be able to choose the most suitable motor for your project referring to the table below:

Source: core.ac.uk

At Niryo, our six axis collaborative robots rely on two types of motors: the custom-made stepping motors and the servomotors XL330 and XL430.

The stepper motors are being used for the first three axes: base, shoulder, and elbow, in order to guarantee an acceptable power density and an adequate torque.

On the other hand, the servo DC motors were chosen for the other three axes: forearm, wrist, hand. This choice was made to ensure a good speed along with a fair overload capacity, but also because of their compact size and light weight.

We should note that both types are considered as affordable so that the final price of the robot stays in the range of acceptable, while keeping it possible to ensure that the robot operates effectively and provides a valuable learning experience for students!

And while we’re at it… a sneak peak into our French factory, where motors are of course on the assembly line.

Thanks for reading, for additional info, get in touch with us, we answer promptly.