Empower your robotics potential.

We elevate people’s life through affordable

robotic arm solution that anyone can use.

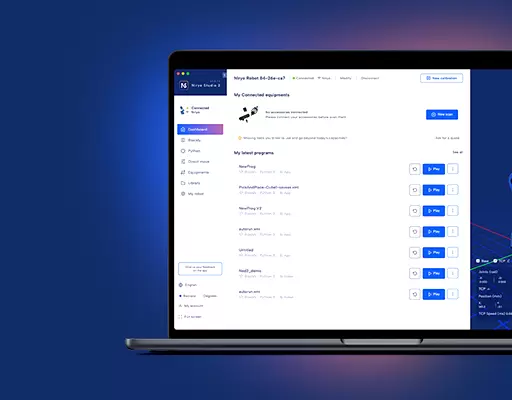

NiryoStudio

Plug and Play 6 axis robotic arm with a unique experience.

5 min. to install

Every day life to enjoy your robotic experience

From Blockly to Python

Unlock features and explore the world of robotics.

Ecosystem

A whole Ecosystem that unlocks unlimited Possibilities.

The Niryo experience extends far beyond purchasing robots. It’s an all-inclusive solution comprising hardware, software, and comprehensive documentation, enabling exploration of multiple applications.

Niryo

Docs

Docs

Niryo

Academy

Academy

Niryo

Studio

Studio

You will never see a

6 axes robots with

so many possibilites.

Testimonials

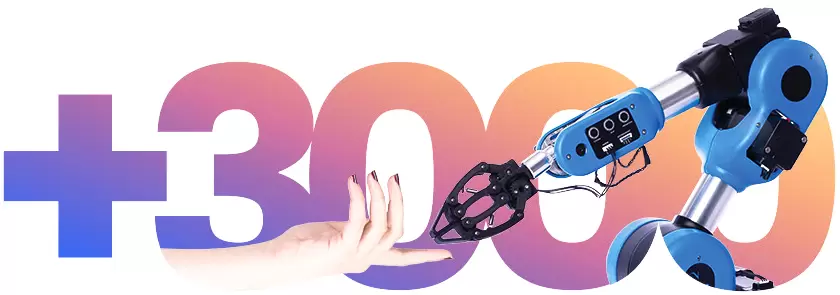

+300 universities including the world’s top 50

Testimonials

+200 companies growing with Niryo

Testimonials

Discover how Niryo's robotic arms are used

Polytech Lille x Niryo

We visited the Polytech engineering school in Villeneuve d’Ascq, near Lille (France). They use the Niryo robot to reproduce its movements through AI

Esirem’s Condorcet University x Niryo

We visited Esirem’s Condorcet University in Le Creusot (France) where robotics and programming courses are taught. They use Ned2 robot for reproducing sign language are thaught.

ITII Mecavenir X Niryo

Worskshop training for managers and engineers of tomorrow (card-video)

Deutsche Bahn X Niryo

Vocational training facilitated by cobots

Marcel Häßler

Quality and Industrialization Manager

Digital transformation interests us from a business point of view, but it is also important to us in the field of professional training because it raises awareness of lean methods (…) We take advantage of the intelligence of the robot ecosystem.

Hakim Latrache

Head of the Embedded Electronics Systems Section

Our engineering school has chosen to invest in 20 Niryo robots in order to allow each apprentice to program his own. They are used for different lessons such as mechanics, mathematics, programming of embedded systems, and of course robotics. Our purchase has allowed, after only one year of use, to train more than 100 apprentices!

Gaël Chèné

Quality and Industrialization Manager

The robot is easy to apprehend, anyone can program it and for us it is perfect. When we make a mistake, we can rectify it quickly.

Imed Nasri

PhD automatic engineer / industrial IT

Ned2 provide a rewarding experience for student. It allows them to have a better understanding and utilisation of collaborative robots.

Marcel Häßler

Quality and Industrialization Manager

Digital transformation interests us from a business point of view, but it is also important to us in the field of professional training because it raises awareness of lean methods (…) We take advantage of the intelligence of the robot ecosystem.

Hakim Latrache

Head of the Embedded Electronics Systems Section

Our engineering school has chosen to invest in 20 Niryo robots in order to allow each apprentice to program his own. They are used for different lessons such as mechanics, mathematics, programming of embedded systems, and of course robotics. Our purchase has allowed, after only one year of use, to train more than 100 apprentices!

Gaël Chèné

Quality and Industrialization Manager

The robot is easy to apprehend, anyone can program it and for us it is perfect. When we make a mistake, we can rectify it quickly.

Imed Nasri

PhD automatic engineer / industrial IT

Ned2 provide a rewarding experience for student. It allows them to have a better understanding and utilisation of collaborative robots.

Niryo’s collaborative robots

are supporting humans around the world

Discover multiple kit for everyone.